BI SOLAR EVERTEC – PRE-INSULATED PIPES FOR SOLAR PANELS

The BI SOLAR EVERTEC solution is a complete system of pre-insulated twin pipes for solar systems.

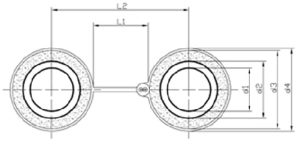

The core products is a corrugated steel twin pipe, made of stainless steel, manufactured in accordance with the European standards: 1.4404/AISI 316L and 1.43301/AISI 304. The pipe is coated with a protective PVC shell, with an electric cable installed inside the shell. The most distinctive quality of the pipes is its aerogel insulation demonstrating an extremely low heat transfer coefficient (λ=0.0175W (mˑK under average temperature of 10°C acc. to EN 12667:2002). Pipes are available in diameters ranging from DN12 to DN40. The standard insulation thickness values are 6mm and 11mm.

Benefits

- High energy performance

- Low thickness of the insulation material

- High durability

- Simple installation

- High fire safety

- No hazards in case of panel stagnancy, due to broad range of operating temperatures, ie. -200°C to +300°C (-328°F to 572°F).

- Quality Assurance Certificate issued by TÜV Rheinland.

Steel pipes | Mark | DN16 | DN16 | DN20 | DN20 | DN25 | DN25 | DN32 | DN32 | DN40 |

Pipe type |

| 316L | 316L | 316L | 316L | 316L | 316L | 316L | 316L | 316L |

Insulation thickness [mm] | ga | 6 | 11 | 6 | 11 | 6 | 11 | 6 | 11 | 11 |

Pipe’s inner diameter [mm] | d1 | 16.2 | 16.2 | 20.9 | 20.9 | 25.3 | 25.3 | 33.9 | 33.9 | 39.8 |

Pipe’s outer diameter [mm] | d2 | 21.4 | 21.4 | 26.3 | 26.3 | 31.8 | 31.8 | 40.7 | 40.7 | 49.8 |

Tolerance [mm] | w | 0.2 | 0.2 | 0.2 | 0.2 | 0.4 | 0.4 | 0.3 | 0.3 | 0.4 |

Min. bending radius [mm] | Rg | 25 | 25 | 30 | 30 | 40 | 40 | 50 | 50 | 60 |

Nominal pressure acc. to DIN EN ISO 10380/SF4 | pmax | 10 | 10 | 10 | 10 | 6 | 6 | 2.5 | 2.5 | 2.5 |

Pipe’s unit weight [kg/m]* | mjr | 0.820 | 1.140 | 0.980 | 1.410 | 1.160 | 1.920 | 2.133 | 2.730 | 3.200 |

Pipe’s axial clearance [mm]* | L2 | 59.4 | 71.4 | 64.3 | 76.3 | 69.8 | 81.8 | 78.7 | 90.7 | 99.8 |

Aerogel insulation |

|

Heat conductivity coefficient under 10°C (acc. to PN-EN 12667:2002) | 0.0175W/mK |

Maximum operating temperature | 675°C (1247°F) |

Reaction to fire class acc. to PN-EN 13501-1:2019 | A2-s1, d0 |

PVC |

|

Thickness | 0.5mm |

Tensile strength | 1800N/5cm |

Reaction to fire class acc. to EN 13501 | B1-s2, d0 |

Specific weight | 650g/m2 |

UV-radiation resistance | Very high |