PRE-INSULATED PIPES FOR SOLAR INSTALLATIONS.

BiSolar offers a complete system of pre-insulated double pipes for solar installations.

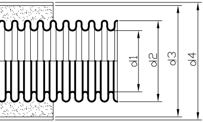

STEEL PIPE

The base is made of a stainless steel corrugated pipe, made in

accordance with European standard 1.4404/AISI 316L from the

highest quality high-alloy steel with a very small amount of carbon,

plus chromium and nickel. This chemical composition guarantees

the low corrosivity, high durability and elasticity of the pipe.

AEROGEL BLANKET

The distinctive feature of BiSolar pipes is the use of high quality

insulation in the form of an aerogel mat, which has excellent

thermal insulation properties. The very low thermal conductivity

coefficient (λ=0.018W/mK) means that only a low insulation

thickness is needed – as little as 6.5 mm – to achieve the same

properties that competing products reach with a thickness

of 15 mm.

PVC COATING

Everything is protected by high quality PVC, which is resistant to the

effects of UV rays. The coating provides protection against external

factors, birds and rodents.

ELECTRICAL CABLE

The attached electrical cable connects to the temperature sensor.

The cable is covered in an additional silicone sleeve which is

resistant to high temperatures.

- HIGH ENERGY EFFICENCY

BiSolar pipes ensure a high level of solar

energy utilisation in solar installations,

guaranteeing the least possible heat

loss and the high efficiency of the solar

collectors thanks to the unique properties

of the aerogel insulation material. - LOW INSULATION THICKNESS

The aerogel mat is almost three times thinner than the material used in

conventional products, while maintaining insulation properties at the

same level. This allows the installation of BiSolar pipes in roofing, partition

structures and ventilation ducts. The use of thinner insulation also reduces the

space required for transportation and storage of the pipes. - HIGH DURABILITY

Using the highest quality materials in

BiSolar pipes means that the product

is exceptionally durable, its insulating

properties do not change over time,

and the additional layer of durable PVC

effectively protects against external

factors, rodents, birds and UV rays. - SIMPLIFIED INSTALLATION

The assembly of BiSolar pipes is not complicated.

The mounting flange of each pipe enables simple

installation on a minimum surface using ordinary

screws. No clamps are required.

Thanks to the reduced outer diameter of the pipes,

they can be mounted directly under roof tiles,

eliminating the need for expensive shaped tiles. - FIRE SAFETY

The materials used to produce BiSolar pipes have

a very high fire resistance class and are classified

as non-flammable or not easily flammable.

| Steel pipes | Symbol | Unit |

|

||||||

| Insulation thickness | ga | mm |

|

||||||

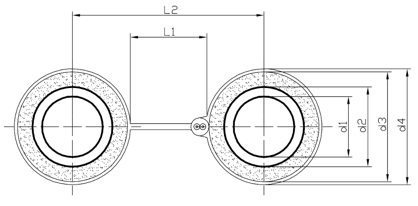

| Inner diameter of pipe | d1 | mm |

|

||||||

| Outer diameter of pipe | d2 | mm |

|

||||||

| Tolerance | w | mm |

|

||||||

| Wall thickness of pipe | gr | mm |

|

||||||

| Min. bending radius | Rg | mm |

|

||||||

| Nominal pressure according to DIN EN ISO 10380/SF4 |

pmax | mm |

|

||||||

| Unit mass of pipe | mjr | kg/m* |

|

||||||

| Thermal resistance | Ri | mK/w* |

|

||||||

| Axial spacing of pipes | L2 | mm* |

|

||||||

| Outer diameter of pipe | d4 | mm* |

|

||||||

| *the values relate to the whole finished product: double pipe with insulation, cable and PVC |

| thermal conductivity coefficient (TCC) (according to EN 12667, tav = 10°C) |

0,018 W/mK | ||

| maximum application temperature | 675°C | ||

| permissible stagnation temperature of the collector according to EN 12975-2 |

675°C | ||

| fire classification according to EN 13501 | A2-s1 d0 | ||

| water and moisture resistance | hydrophobic material | ||

PVC

| thickness | 0,5 mm | ||

| tensille strength | 1800 N/5 cm | ||

| weight | 650 g/m2 | ||

| fire classification according to EN 13501 | B1-s2 d0 | ||

| UV resistance | very high | ||

Electrical cable

| type | SiHF 2×0,75 | ||

| maximum application temperature | 180°C | ||

| extra casing | silicone insulation | ||