The new generation pre-insulated domestic hot water piping, insulated with aerogel mat with especially low heat loss.

WATCH VIDEO

B EverWarm is based on a 5-layer Pex-Al-Pex piping of ∅ 16 ×2 mm and ∅ 20×2 mm dimensions, certified by the National Institute of Hygiene (PZH), insulated with aerogel mat providing 5 mm or 10 mm of insulation.

Max. working temperature: 95°C

Max. working pressure: 10 bar

Insulation color: white

The new generation pre-insulated domestic hot water piping EverWarm, insulated with aerogel mat is available in the following versions:

AS 5 type with Pex-Al-Pex piping of the following dimensions :

- ∅ 16 ×2 mm

- ∅ 20 ×2 mm

- factory pre-insulated with an aerogel mat providing 5 mm of insulation

AS 10 type with Pex-Al-Pex piping of the following dimensions:

- ∅ 16 ×2 mm

- ∅ 20 ×2 mm

- factory pre-insulated with an aerogel mat providing 10 mm of insulation

EverWarmsolutions are a complete pre-insulated piping system intended mainly for DHW installations, especially in systems with water -circulation.

All pre-insulated pipes have a PE protective coating.

A unique feature of all EverWarm piping is the aerogel insulation with exceptionally low heat transfer coefficient (λ = 0.017 W/(m•K) in C temperature according to PN-EN 12667:2002) .

The whole pipe is enveloped in a PE protective coating which protects the pipe from external factors

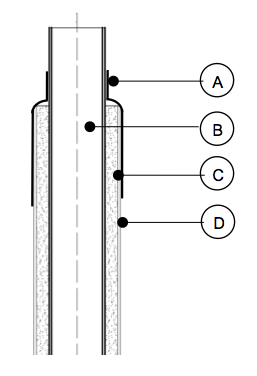

- A – Heat-shrinkable sleeve

- B – Pex-Al-Pex pipe

- C – Aerogel mat

- D – PE protective coating

BENEFITSTECHNICAL SPECIFICATION OF PIPESTECHNICAL SPECIFICATION OF PIPING INSULATIONSYMBOL SPECIFICATION FOR PIPESVIDEO

- Extremely high heat savings in comparison with commonly utilized polyurethane foam insulation of comparable thickness.

- High durability and safety of the installation due to adoption of nanotechnology in thermal insulation.

- Due to low heat losses in DHW installation, the EverWarm pipingensures high degree of coverage of DHW preparation heat by the solar panels.

- Due to reduced heat losses in DHW installation, the annual coefficient of performance SPF/JAZ/SCOP of the heat pump-equipped installation is maintained on high level due to reduced heat pump operation time at elevated parameters of heating water. .

- Piping insulation is more than three times thinner in comparison with conventional solutions while maintaining the same thermal resistance.

- High degree of insect, rodent and bird protection due to aerogel inedibility.

- Long service life confirmed by positive test results during simulated ageing time of 60 years

- Optimal space utilization in construction bulkheads, floor screed and wall grooves due to low insulation thickness.

- The pipes can be installed near a water installation, central heating or sewage piping as well as ventilation ducts.

Piping type

|

Symb. |

Unit |

AS 5 |

AS 10 |

| Pipe nominal diameter |

DN |

mm |

|

|

| Inner diameter |

d1 |

mm |

|

|

| Outer diameter |

d2 |

mm |

|

|

| Tolerance |

w |

mm |

|

|

| Pipe wall thickness |

gr |

mm |

|

|

| Thickness of aerogel insulation |

ga |

mm |

|

|

| Outer diameter of pipe insulation |

d3 |

mm |

|

|

| Outer diameter of the jacket |

d4 |

mm |

|

|

| Min. bending radius |

Rg |

mm |

|

|

| Max. working pressure |

pmax |

bar |

|

|

| Max. working temperature |

tmax |

oC |

|

|

| Piping wall thermal resistance*1 |

RM |

m·K/W |

|

|

| Insulation thermal resistance*2 |

RIA |

m·K/W |

|

|

| Heat transfer resistance*3 |

ROA |

m·K/W |

|

|

| Unitary heat losses*4 |

UR |

W/m·K |

|

|

| Unitary piping volume |

vj |

l/m |

|

|

| Unitary weight of piping with insulation*4 |

mj |

kg/m |

|

|

|

Symb. |

Unit |

|

| Insulation type |

– |

– |

nanostructured aerogel mat |

| Heat transfer coefficient |

l |

W/(m·K) |

0,017 ( acc. to PN-EN 12667:2002) |

| Working temperature range |

tz |

0C |

-200 to +200 |

| Aerogel melting point |

tt |

0C |

850 ( preserves properties up to 650 0C) |

| Density |

rz |

kg/m3 |

ca. 150 |

| Fire classification |

|

|

C-s1 d0 according to EN 13823 and PN-EN 11925 – 2 |

| Water and moisture resistance |

|

|

hydrophobic |

| Acoustic wave velocity |

u |

m/s |

< 100 ( good acoustic insulation ) |